Categories

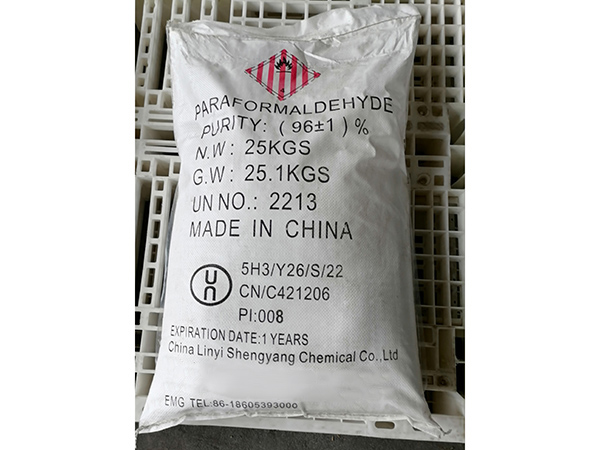

- 96%powder Paraformaldehyde

- 96% crystalline particles Paraformaldehyde

- 92% crystalline particles Paraformaldehyde

- Export paraformaldehyde

- Formaldehyde

- Methanol

- Acrylic acid

- Butyl acrylate

News

[paraformaldehyde] rela...

[Liquid formaldehyde p...

[Shandong urine aldehyd...

【 paraformaldehyde 】 ...

Linyi Guansheng Chemical Co. LTD

18605393000

Contact: Manager Li

Contact number: 18605393000 (wechat synchronization)

Address: Linyi Economic and Technological Development Zone

NEWS

[Paraformaldehyde] It is a safe mixture

96%powder Paraformaldehyde (CH2O) n, also known as solid formaldehyde, formaldehyde polymer, low molecular weight formaldehyde polymerization degree n is about 8-12, solubility is 80, there is a strong smell of formaldehyde, polymerization degree n in more than 12 solubility is 120-170, insoluble in ethanol, propyl alcohol and ether, soluble in dilute acid and dilute alkali solution, melting decomposition quickly,Does not have some mechanical properties of plastic, and can not be processed into a film, can be used as disinfectants, fungicides and the manufacture of resin and artificial ivory, can be pure formaldehyde under alkaline conditions by polymerization.

Paraformaldehyde is produced by dehydration, concentration and drying of formaldehyde, and its production is divided into two steps: first, 37% of formaldehyde is heated under negative pressure to remove part of the water, concentrated into 65%-70% concentrated aldehyde under the condition of alkaline catalysis polymerization, and then the finished product is dried. It is worth noting that:In order to reduce the loss of aldehydes, the boiling point needs to be reduced, so the above processes are carried out under vacuum negative pressure.

Recommended

Contact:Mr. Li

Number:18605393000

Address:Linyi Economic and Technological Development Zone

Scan code

Back

Back