Categories

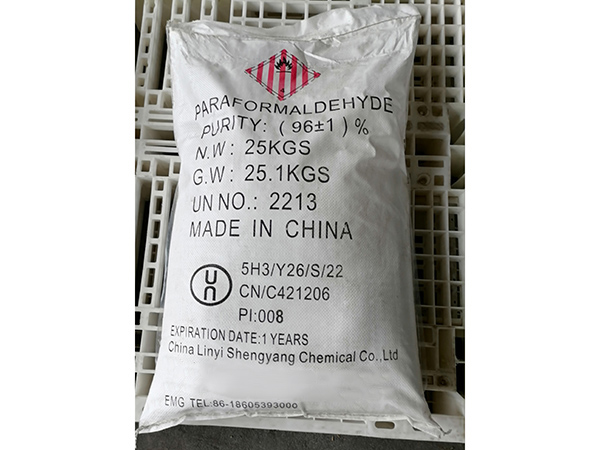

- 96%powder Paraformaldehyde

- 96% crystalline particles Paraformaldehyde

- 92% crystalline particles Paraformaldehyde

- Export paraformaldehyde

- Formaldehyde

- Methanol

- Acrylic acid

- Butyl acrylate

News

[paraformaldehyde] rela...

[Liquid formaldehyde p...

[Shandong urine aldehyd...

【 paraformaldehyde 】 ...

Linyi Guansheng Chemical Co. LTD

18605393000

Contact: Manager Li

Contact number: 18605393000 (wechat synchronization)

Address: Linyi Economic and Technological Development Zone

NEWS

[Shandong urine aldehyde glue] Understanding it is like understanding a safety

Due to the shortcomings of Shandong urine aldehyde adhesive, such as poor initial viscosity, large shrinkage, brittleness, water resistance, easy aging, formaldehyde release and curing release of formaldehyde pollution to the environment, damage to health and so on, it must be modified to improve the performance and expand the application.The modification methods are simply listed as follows:

1, improve the initial viscosity: to improve the initial viscosity of Shandong urine aldehyde glue, can be added to polyvinyl alcohol, polyethylene glycol, hydroxymethyl cellulose and other modifiers, but the price of these substances is high, so can choose starch substances, especially starch in the beginning of the synthesis of urea-formaldehyde resin to join, the effect is better.During the synthesis process, starch may undergo hydrolysis, resulting in various dextrins, etc. Due to the high relative molecular weight of starch, the viscosity after dissolution is also very high, adding a small amount of starch can produce urea formaldehyde resin with high viscosity.At the same time, the hydroxyl group, hydroxymethyl group and aldehyde group on starch chain may participate in the synthesis of ureA-formaldehyde resin, which not only improves the initial viscosity, but also improves the bonding strength and storage stability.

2, reduce shrinkage: Shandong urine aldehyde adhesive curing shrinkage rate is large, easy to crack, the adhesive layer produces internal stress, so that the viscosity strength decreases.In order to reduce the shrinkage rate of urea-formaldehyde resin curing, some fillers are usually added to the resin glue, such as flour, starch, blood powder and A-cellulose powder, wood powder, soybean powder and so on.

Recommended

Contact:Mr. Li

Number:18605393000

Address:Linyi Economic and Technological Development Zone

Scan code

Back

Back